RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Expert Wastewater Servicing: Optimising Performance & Ensuring Reliability

At RA Dalton, we know that keeping a wastewater treatment system in peak condition takes more than routine checks – it requires technical expertise, attention to detail and a proactive approach. In this recent case study, our engineer completed a comprehensive service visit to a site featuring a Klargester Bioficient 55 and a Twin Effluent Pump Station, ensuring both systems remain efficient and compliant.

Inspection and Maintenance of the Klargester Bioficient 55

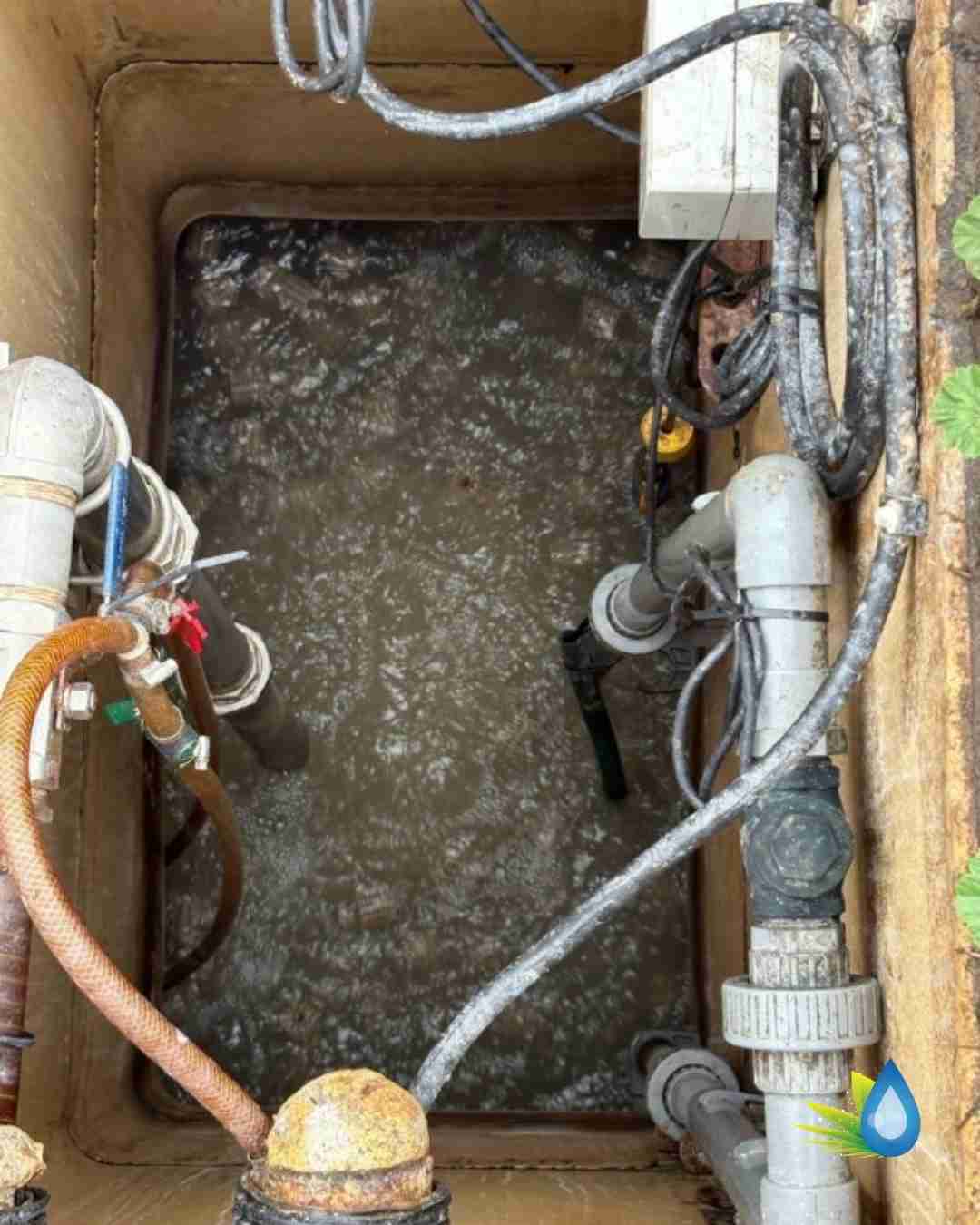

On arrival, the Bioficient 55 was operating correctly, with tank levels within specification. The primary chamber was free of solids, but the water appeared very white, a sign of greases and chemical residues. The treatment zones were aerating as expected and the final settlement showed similar discoloration.

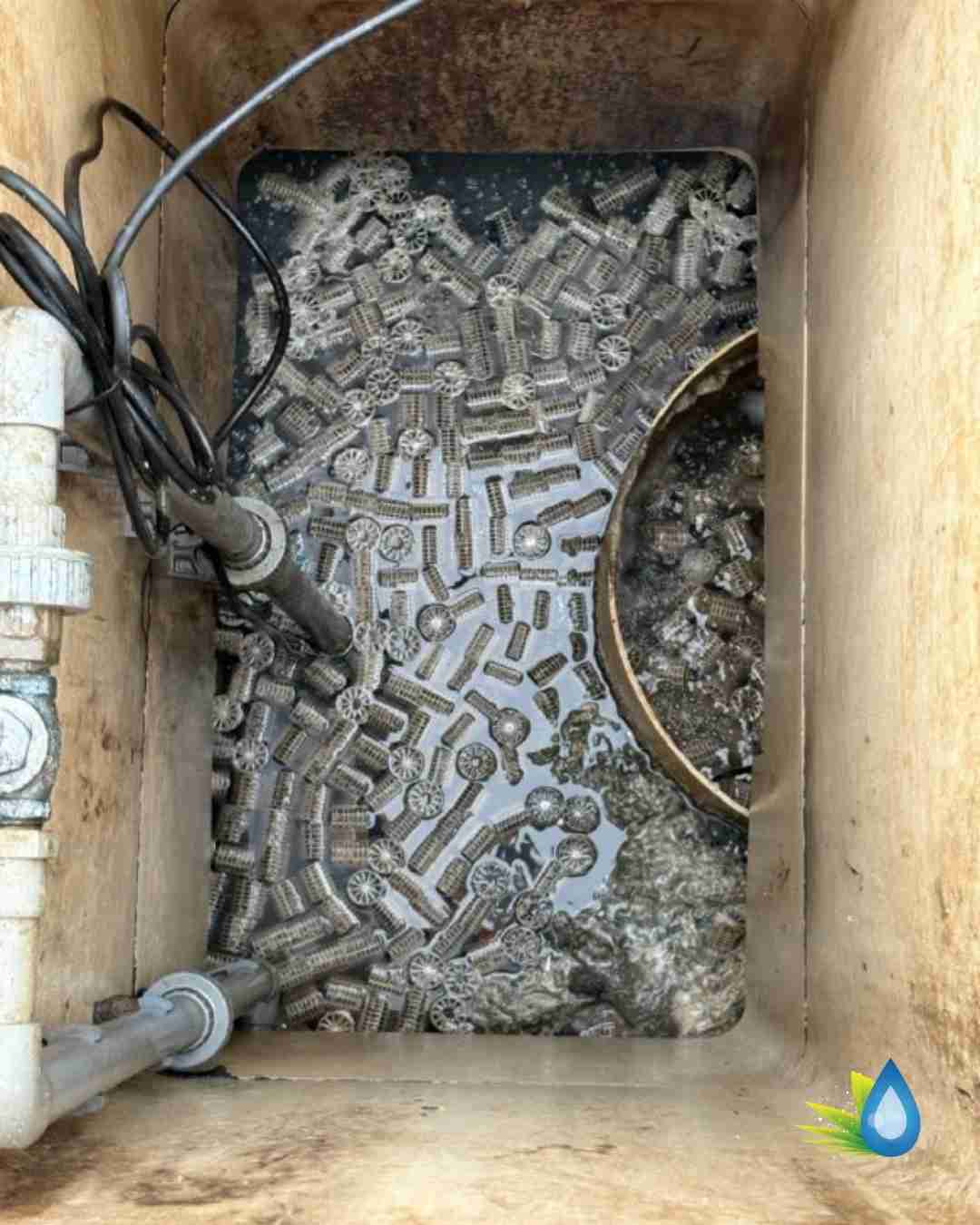

Our engineer carried out a full service on the Klargester Bioficient 55, starting with the removal and inspection of the pumps to check for blockages and confirm they were operating correctly. The diffuser pipes, airlines, and airlift system were examined and found clear and fully functional, while the electrical junction box and blower connections were secure and working as expected. Filters in the FPZ, JDK and Hiblow units were cleaned and replaced to maintain optimal airflow. Finally, the control panel and warning devices were tested to ensure full operational reliability.

✅ Recommendation: Monitor water quality and review chemical inputs to prevent future discoloration.

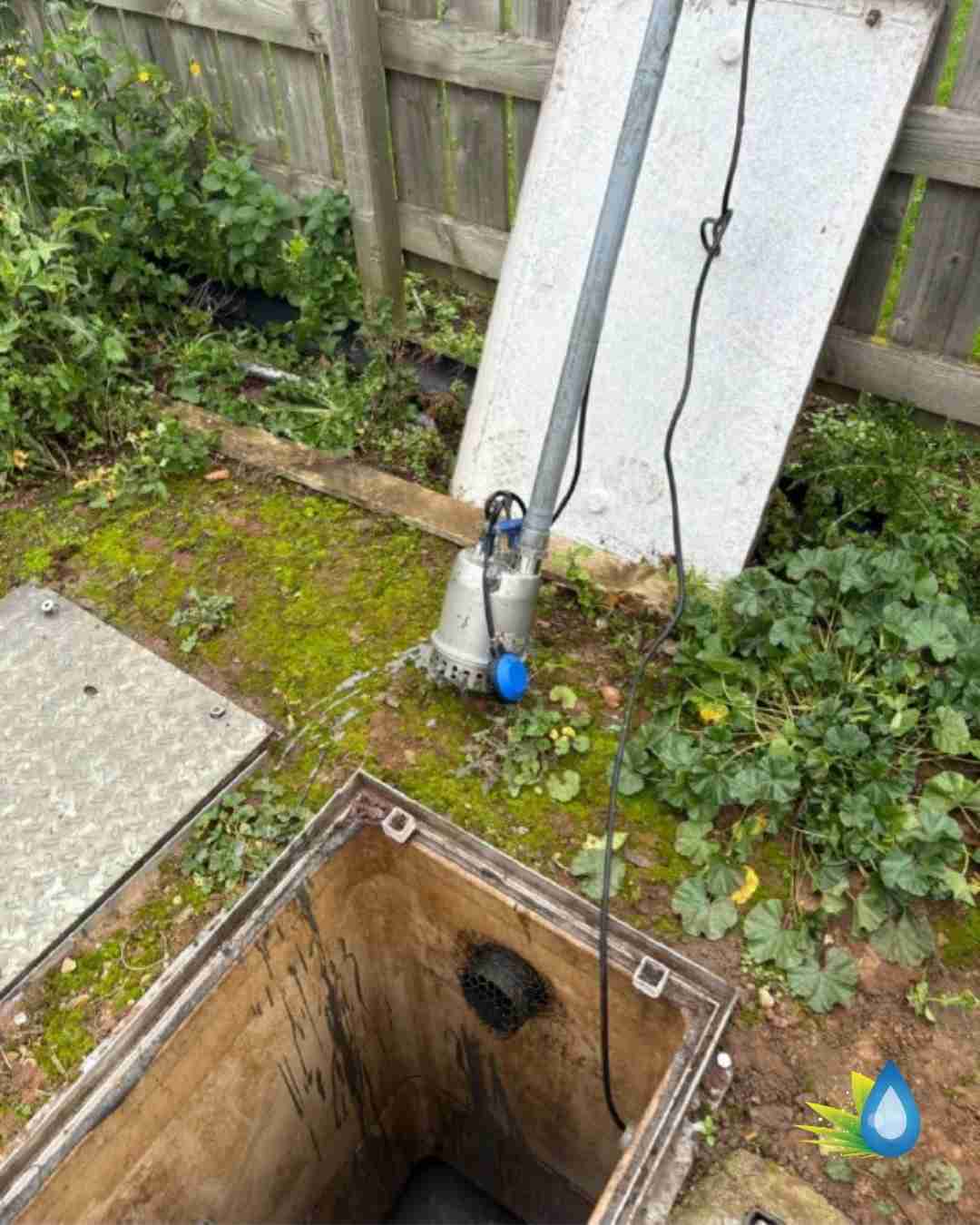

Servicing the Twin Effluent Pump Station

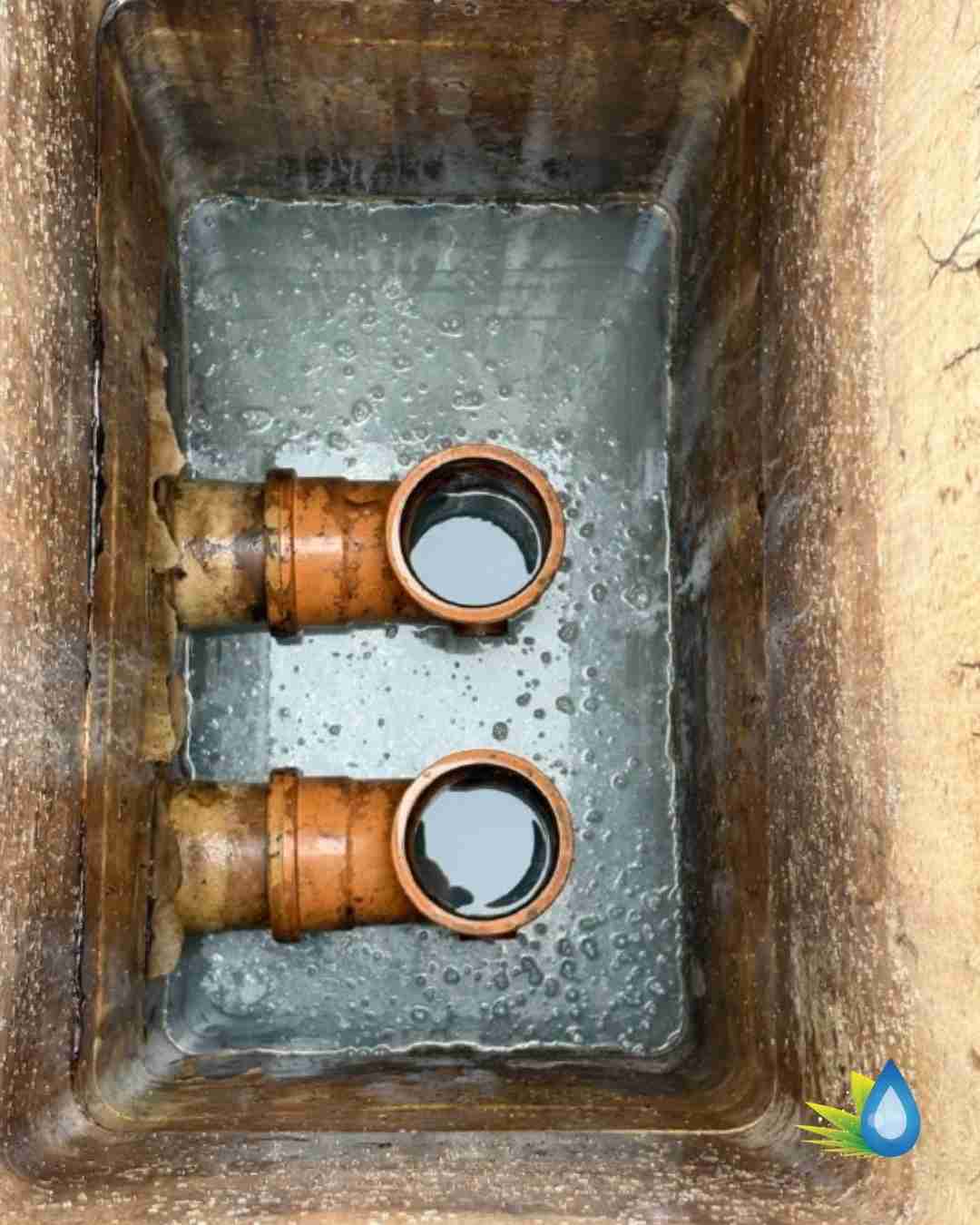

The Twin Effluent Pump Station was also thoroughly serviced to ensure reliable operation. Levels were correct and the station was in a clean condition, though the water remained milky, consistent with the treatment tank output.

Our engineer cleaned and tested the floats, confirming they were functioning correctly, before inspecting both pumps for blockages and verifying they operated as expected. The non-return valve was checked prior to reinstalling the pumps, and amp readings were taken, showing a consistent 2.6 amps per pump—well within the normal range. Finally, the control panel and warning devices were tested to guarantee full functionality and responsiveness.

✅ Recommendation: Continue routine servicing and monitor for chemical carryover to maintain pump efficiency.

So, why Does Wastewater Appear Milky in a Bioficient System?

Milky or white wastewater in a Klargester Bioficient 55 is often a sign of chemical imbalance rather than a mechanical fault. Common causes include:

- High levels of fats, oils, and greases (FOG) entering the system, which can coat surfaces and affect settlement.

- Detergents and cleaning chemicals from kitchens or industrial processes, which introduce surfactants that create a cloudy appearance.

- Overloading of chemical-based products, such as disinfectants or bleach, which disrupt the biological treatment process and prevent bacteria from breaking down waste effectively.

- Low biological activity due to chemical shock or irregular loading, meaning solids aren’t fully digested before reaching the settlement zone.

While milky water doesn’t indicate immediate failure, it can reduce treatment efficiency and lead to compliance issues if left unchecked. Regular servicing and monitoring chemical inputs are essential to maintaining clear, healthy effluent!

Preventative Maintenance Matters

This visit demonstrates the value of proactive servicing. By addressing both mechanical and biological aspects of these systems, we help clients avoid costly breakdowns and maintain environmental compliance.

Need a service or advice?

📞 Call us on 01388 537050 📧 Email info@radalton.co.uk