Klargester Clearwater BTA 3: FAQ’s & the Ideal Installation

Klargester Clearwater BTA 3: FAQ’s & the Ideal Installation

The Clearwater BTA Economy Range emerge as a prominent choice for their efficiency and effectiveness for domestic households. However, understanding the nuances of sewage treatment systems, particularly regarding specific products like Clearwater BTA Systems, can be complex. To demystify this topic, let’s explore some frequently asked questions (FAQs).

- What exactly is a Klargester Clearwater BTA?

A Clearwater BTA (Biological Treatment Aerated) is Klargesters economy range of sewage treatment system designed to efficiently treat domestic sewage at a lower initial price.

- How does a Klargester Clearwater BTA System work?

The wastewater enters the primary settlement chamber of the Clearwater BTA Airflow System, where solid particles settle to the bottom and are partially decomposed by anaerobic bacteria. The clarified effluent then flows into the aeration chamber, where air is introduced through diffusers from an air blower situated on a platform above ground. This aeration process promotes the growth of aerobic bacteria, which further break down organic matter in the wastewater. The treated effluent is then discharged for further processing or safe disposal.

- What maintenance is required for the Clearwater BTA?

Regular maintenance is essential to ensure the optimal performance of Clearwater BTA Systems. This includes:

- Regular inspections of system components such as blowers, diffusers, and aeration chambers for signs of wear or damage.

- Periodic emptying to remove accumulated sludge and maintain the systems efficiency.

- Schedule servicing by a qualified wastewater engineer to conduct thorough assessments and ensure the Clearwater BTA is operating as it should.

- Are Clearwater BTA Systems suitable for all applications?

Clearwater BTA Systems offer remarkable versatility, making them suitable for a wide range of domestic and commercial applications. However, it’s worth noting that their capacity is limited to 12 persons. For commercial or large-scale needs, it’s advisable to explore options like the Klargester BioAir or BioDisc Range, capable of accommodating anywhere from 8 to 300 persons. Assessing the unique requirements of each application is crucial, and seeking guidance from sewage treatment experts will help identify the ideal system for optimal performance and efficiency.

- What are the steps involved in installing the Clearwater BTA3 sewage treatment plant?

The installation process typically includes setting up the site, delivering the machinery and materials, installing the Clearwater BTA3 in a full concrete surround, using shoring for stability if required, and hiring submersible pumps for dewatering in required circumstances. It also involves installing drainage systems, inspection chambers, and conducting electrical works for system connection and commissioning.

Case Study: Amble, Northumberland

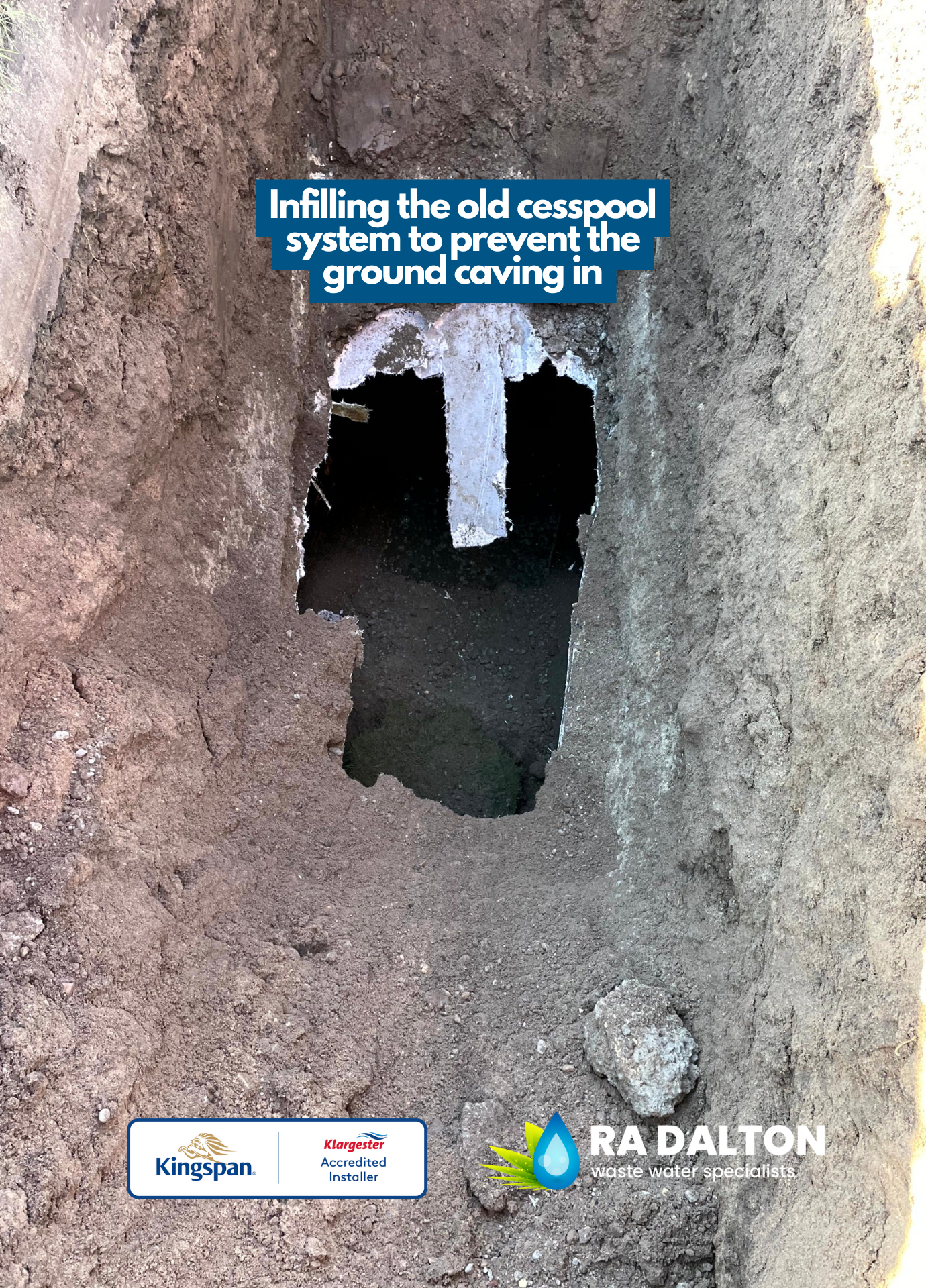

The recent installation of a Clearwater BTA3 IPS sewage treatment plant in Amble to replace a cesspit was a successful process, very closely aligning with the initial quotation. This outcome reflects the profession competence and experience that the RA Dalton installation team have.

The completed job report detailed the actual requirements for the Clearwater BTA3 installation, including:

- 4 meters of 110mm inlet pipework.

- 12 meters of 50mm MDPE for outlet pipework.

- Installation of a 450mm sample point.

- Use of 18 bulk bags of gravel to fill the existing system. Additionally, 5 meters of 2.5 4 core cable and ducting were used for the electricity supply.

By carefully examining the information recorded in the completed job report in comparison to our original quotes, we gain valuable insights into the precision of our estimates, detect any discrepancies, and uphold transparency in our pricing.