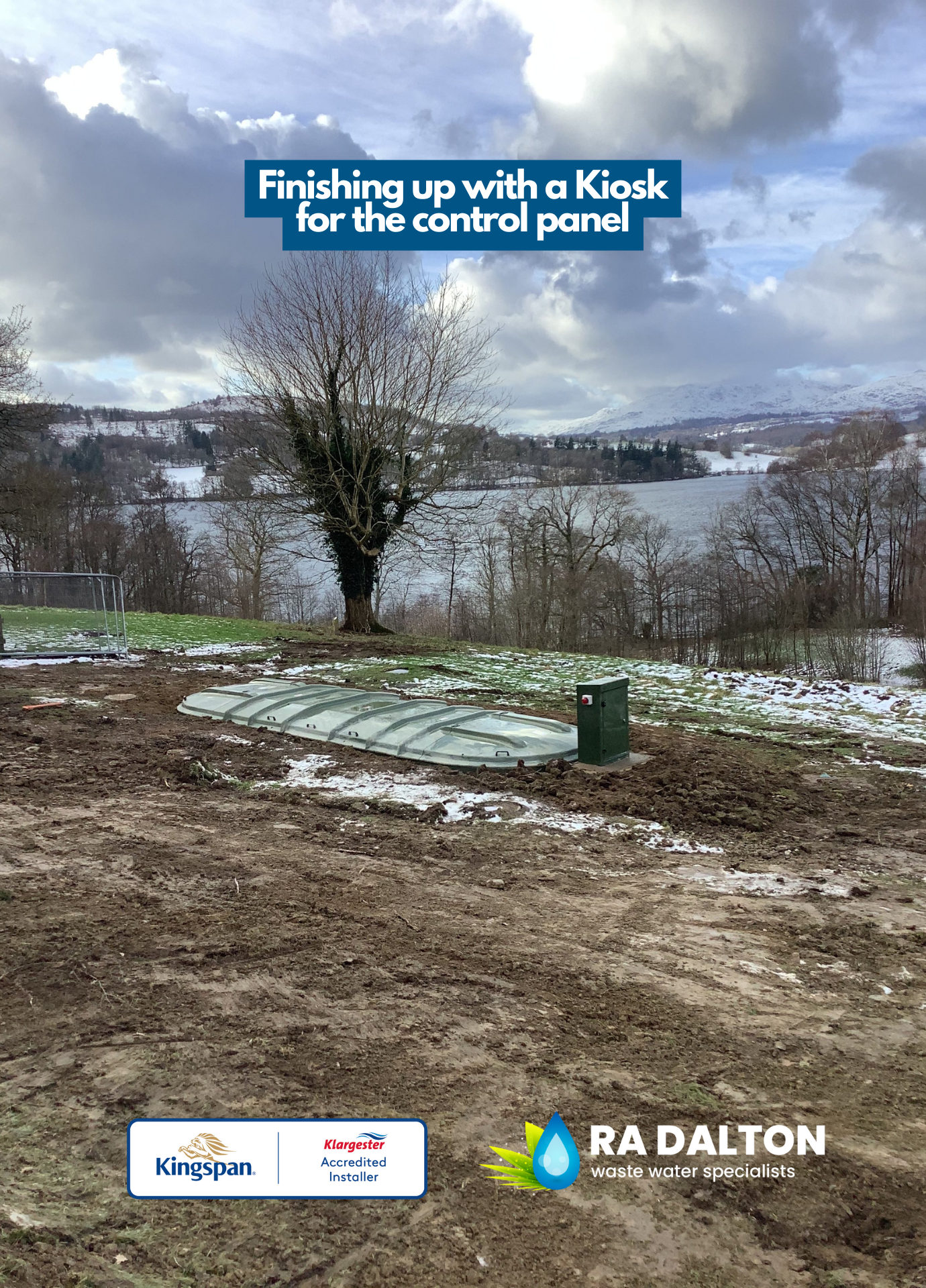

Windermere: Upgrade to comply with Environment Agency

The installation of a sewage treatment plant is no small feat; it demands careful planning, precise execution, and a commitment to the health and safety of all involved. Fortunately for this client, RA Dalton was on the tools.

In this blog post, we detail stages of the installation process, with each phase playing a role in the successful and secure deployment of the Klargester BL BioDisc Sewage Treatment Plant on this beautiful site nestled in Windermere – World Heritage Site.

- Risk Assessment and Method Statement

The foundation of any successful project lies in understanding and mitigating potential risks. Therefore, our journey began with a comprehensive risk assessment and the formulation of a method statement. This crucial step ensured that every subsequent action was guided by a commitment to safety and compliance with industry standards.

- Site Set-Up and Safety Measures

To enhance safety and organisation on this site it was necessary to erect temporary heras fencing to secure and clearly define the working area. Additionally, as part of our standard procedure, we prioritise the welfare of our workforce by arranging for the provision of portable toilet facility alongside the delivery of machinery and materials.

- Environmental Responsibility: Emptying the Old Septic Tank

Before implementing the new system, we emptied the old septic tank, ensuring the responsible disposal of waste with a registered waste carrier.

- Delivery of the Klargester BL BioDisc

Central to our project, the Klargester BL BioDisc was scheduled to be delivered direct to site on the morning of the intended installation once site was prepared accordingly. Our engineers unloaded the unit with the machinery on site, causing as little disruption to the ground as possible.

- Installation: A Full Concrete Surround

Ensuring the stability and longevity of a BioDisc sewage treatment plant is of greatest importance and surrounding it with concrete is essential to prevent potential issues. Without this crucial support, the BioDisc risks instability and could eventually emerge from the ground, rendering the initial installation costs futile. Concrete reinforcement not only secures the unit firmly in place but also safeguards against shifting ground conditions or external pressures. By taking this precautionary measure, we significantly reduce the likelihood of future failures, ensuring a lasting and effective sewage treatment solution.

Concrete is pre-booked weeks in advance ensuring that every step of the install process aligns with the schedule and proceeds according to plan.

- Inspection Chambers and Pipework Installation

To complement the main installation, we addressed ancillary tasks. This included the installation of two inlet and an outlet inspection chambers, as well as laying 24 meters of 160mm pipework to accommodate the new tank location. These tasks contributed to the seamless integration of the sewage treatment plant into the existing infrastructure.

The existing environmental permit mandates that the upgrade from a septic tank to a sewage treatment system must discharge into the pre-existing drainage field on site.

- Integration and Commissioning: Air Lift System and Electrical Connections

This installation extended to internal modifications and pipework for the air lift system, as well as the assembly of a blower box to adapt the existing septic tank to a primary balance tank. Subsequently, the system was set up and commissioned, with electrical works including the connection of 40m of 2.5mm SWA cable from the client’s power supply to the Biodisc.

- Removal of Excavated Spoil

As the project neared completion, we addressed the removal of 11 loads of excavated spoil using grab wagons. This final touch ensured that the construction site was left in a pristine condition, with minimal environmental impact.

- Ongoing Maintenance and Compliance

After successfully completing the installation of this new sewage system, we passed over all necessary details for the ongoing servicing and maintenance of the system. This comprehensive approach ensures that the pristine countryside near Lake Windermere remain safeguarded from any potential sewage pollution from site in the future.