RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Expert Installation of Klargester Grease Trap and Wastewater Storage System for Commercial Butchery Facility

RA Dalton was commissioned to deliver a bespoke drainage upgrade for a commercial butchery site. The project focused on improving the management of processing water, floor washdown, and grease-laden effluent, ensuring compliance with environmental regulations and optimising site hygiene.

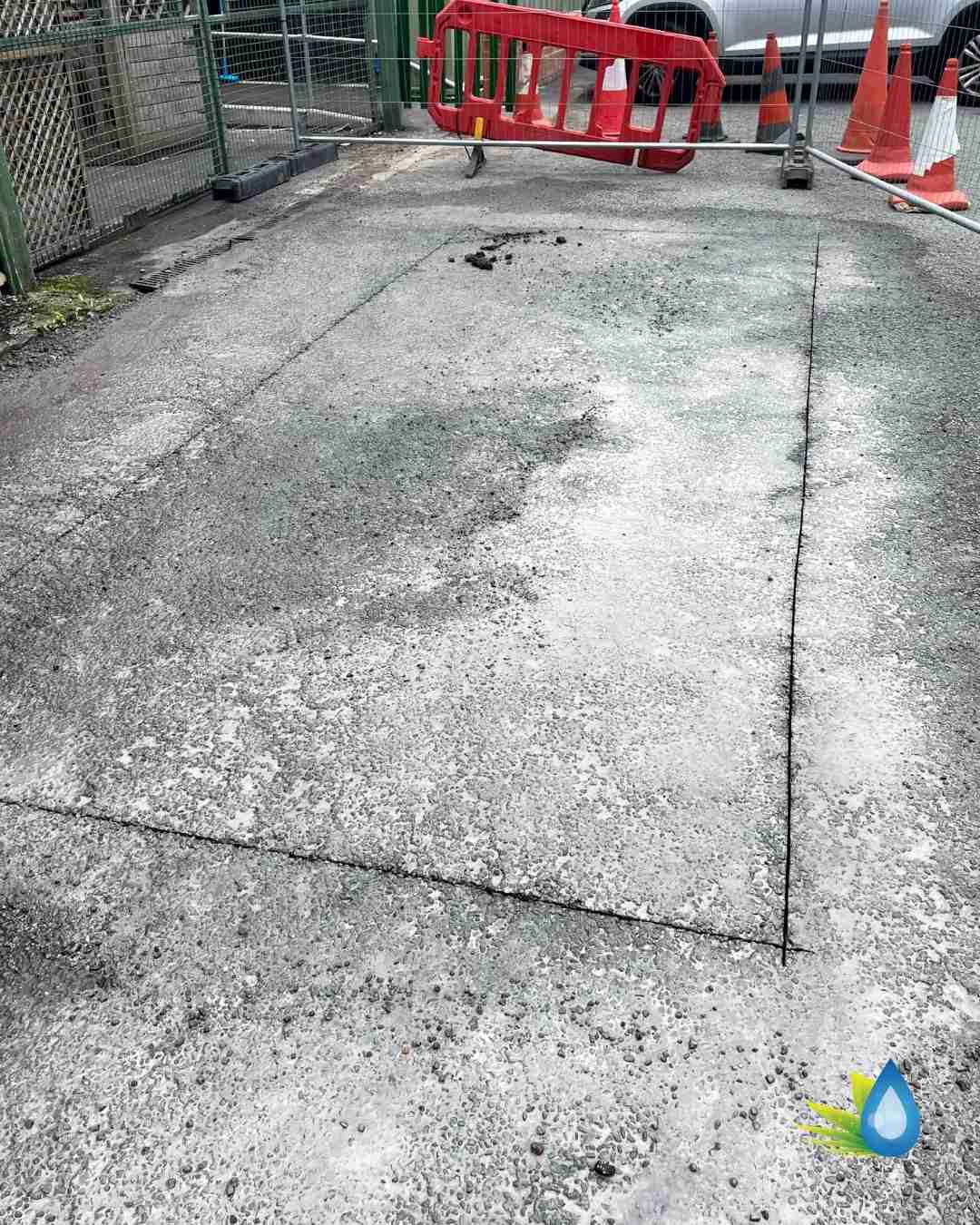

Drainage Inspection and Site Preparation

The project began with a full CCTV drainage inspection to trace all existing pipework connected to butchery and washdown operations. This allowed our engineers to identify a precise connection point for the new wastewater system, ensuring all discharge sources were captured.

To prepare the site, RA Dalton provided:

- Temporary site fencing and portable welfare facilities

- Delivery of heavy plant machinery including a 5–6T excavator and 3T dumper

- Comprehensive Risk Assessments and Method Statements (RAMS) covering all aspects of the proposed sewage treatment works

Health and safety are central to our operations and our team implemented robust controls to manage excavation risks, machinery operation and proximity to live utilities.

Wastewater System Installation Overview

The scope of works included:

- Excavation near the building to locate and divert existing drainage pipework to a new holding vessel location

- Supply and installation of a Klargester NSG14 6,000L grease trap/separator and a 5,700L storage tank

- Installation of a D400 access cover for secure inspection and maintenance

- Spoil removal via grab wagon to maintain site cleanliness

- Breaker hire to manage hard ground conditions, with excavator adjustments for optimal operation

During excavation, our team encountered a large power supply cable, requiring a redesign of the trench layout and additional remedial works to ensure safe installation and structural integrity.

Additional Enhancements

To improve long-term access and durability, RA Dalton supplied and installed three heavy-duty access covers, exceeding the original specification to meet evolving site requirements.

System Benefits and Technical Highlights

The Klargester NSG14 grease trap is designed to efficiently separate fats, oils, and grease (FOG) from wastewater, protecting downstream systems and ensuring compliance with discharge regulations. Paired with the 5,700L storage vessel, this setup offers:

- High-capacity effluent management

- Reduced risk of blockages and contamination

- Easy access for maintenance and inspection

- Durable construction suitable for commercial wastewater environments

This installation demonstrates RA Dalton’s expertise in delivering customised sewage treatment systems for complex commercial applications.

Looking for expert advice on wastewater treatment systems?

Contact RA Dalton today on 01388 537050 or email info@radalton.co.uk to discuss your project requirements.