RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Full Site Wastewater Treatment Service Restores System Integrity and Performance

At RA Dalton, we specialise in delivering expert wastewater management solutions across the UK, helping clients maintain efficient, compliant and environmentally responsible systems.

In this recent multi-phase service visit, our engineers were called to a site requiring comprehensive maintenance across three key components of the wastewater infrastructure: a twin effluent pump station, a WPL sewage treatment system and a single crude pump station.

Each system was professionally cleaned, inspected, serviced and tested to ensure optimal performance, environmental compliance and long-term reliability.

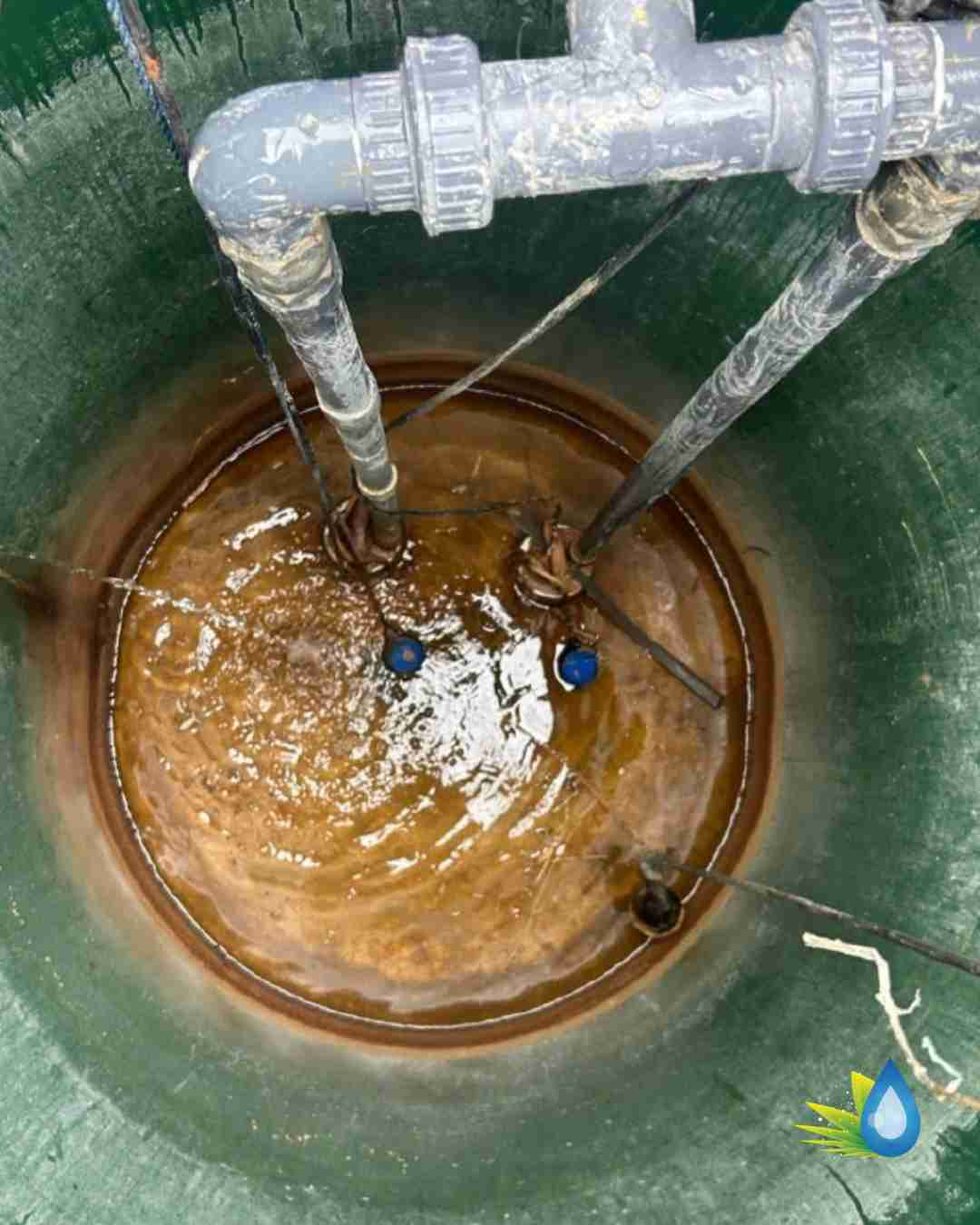

Phase 1: Twin Effluent Pump Station – Preventative Pump Station Maintenance

The first phase focused on the twin effluent pump station, which was operating within normal parameters but required a scheduled routine service to maintain flow efficiency and prevent future faults.

Service Overview:

- Fluid levels were verified and found to be correct.

- Both pumps were lifted and impellers inspected – no blockages or obstructions were found.

- Pumps were tested and confirmed to be pumping efficiently, with electrical amperage within tolerance.

- The control panel and junction box were inspected, and found clean, dry and fully operational.

- The high-level alarm and beacon were tested and functioning correctly.

This proactive effluent pump station service ensured uninterrupted operation and reduced the risk of system failure or emergency callouts.

Phase 2: WPL Sewage Treatment System – Precision Maintenance for Aeration and Flow

Our engineers then serviced the WPL sewage treatment system, which was also functioning well but required detailed servicing of its mechanical components to preserve aeration and biological treatment performance.

Service Highlights:

- System levels were checked and confirmed to be within normal operating range.

- The belt-driven compressor was serviced, including oil replacement and filter inspection.

- Solenoid valves for forward feed and sludge return were tested and found to be working correctly.

- Loss of pressure tests were conducted to verify system integrity.

- The beacon was operational and the control panel was fault-free.

- The treatment unit was then fully emptied using a vacuum tanker.

This service ensured the treatment system continued to aerate effectively and process wastewater as designed, preserving the biological treatment process and ensuring compliance with environmental discharge standards.

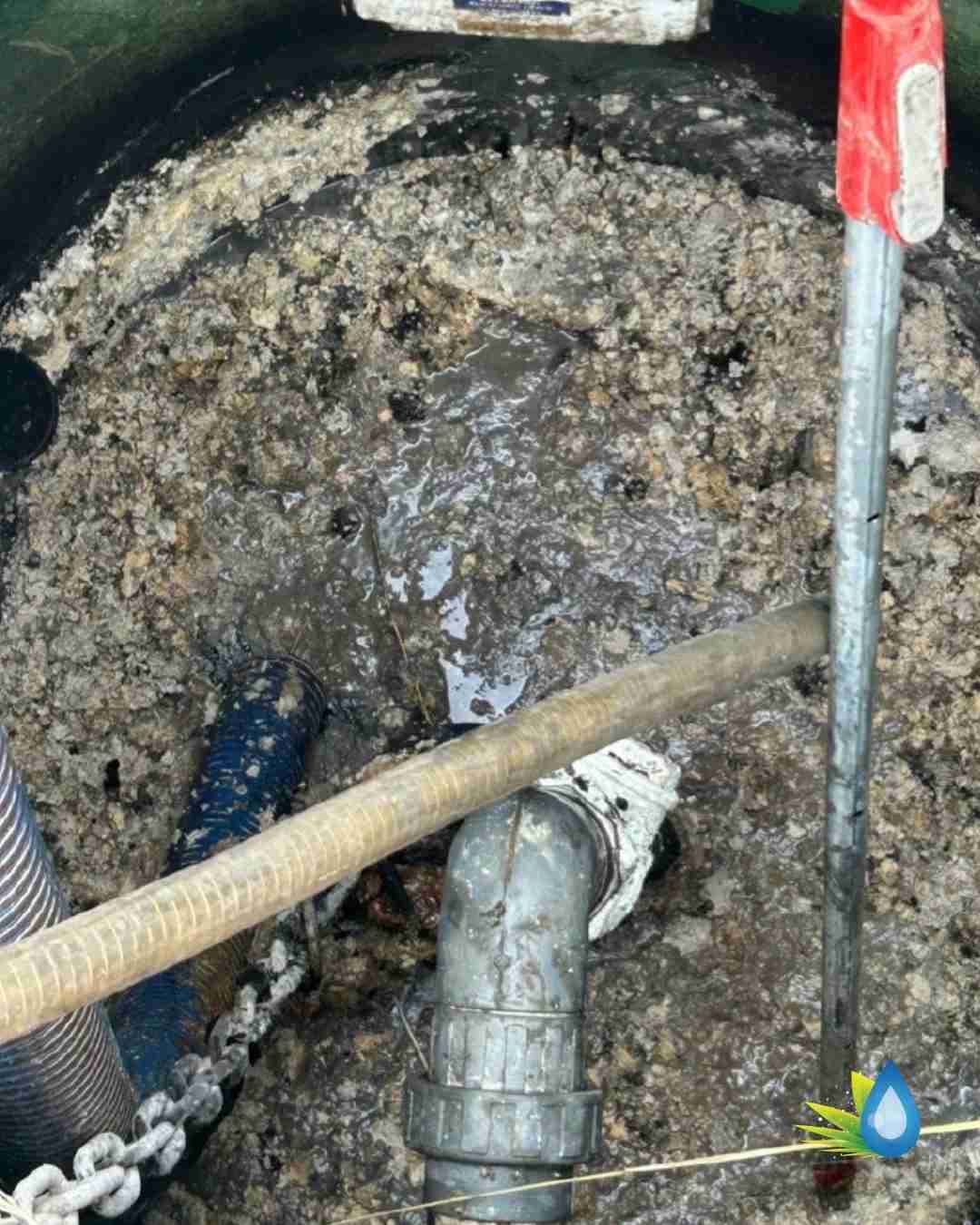

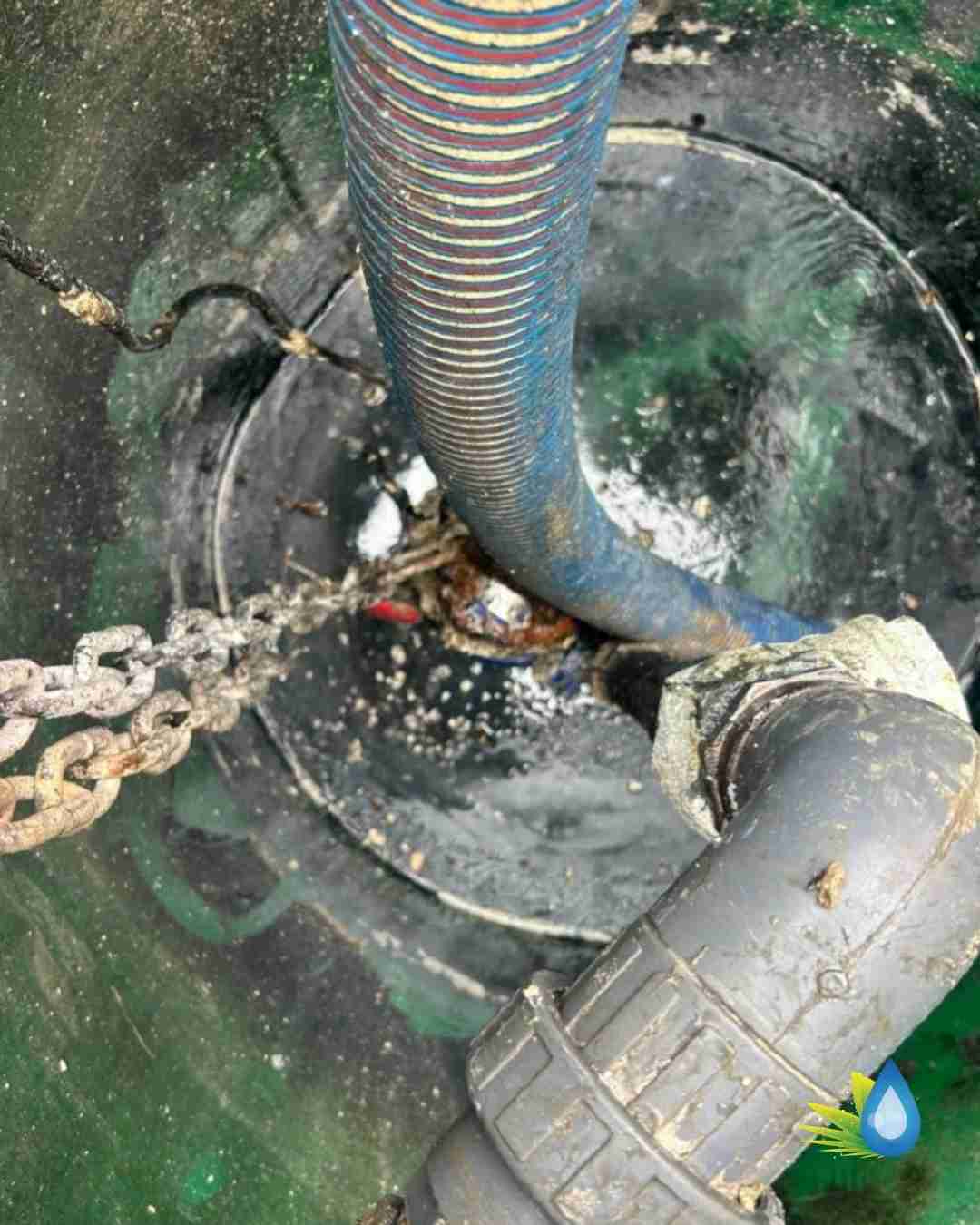

Phase 3: Single Crude Pump Station – Deep Clean to Combat FOG Build-Up

The final phase involved a full clean and inspection of the single crude pump station, which had developed a significant build-up of fats, oil and grease (FOG) – a common issue in wastewater systems that can lead to reduced flow and pump inefficiency.

Service Procedure:

- Fluid levels were correct, but fatty deposits were present throughout the chamber.

- A vacuum tanker was deployed to fully empty and wash down the chamber.

- The pump was lifted and the impeller was inspected – no obstructions were found.

- The integral float switch was cleaned and tested.

- The chamber was refilled with clean water to simulate normal operating conditions.

- The pump was tested and confirmed to be operating within electrical tolerance.

- The control panel and high-level alarm were checked and functioning correctly.

This thorough clean restored the pump station to full working order and mitigated the risk of future blockages.

Outcome: Restored Wastewater Infrastructure and Environmental Compliance

By completing all three service phases with precision and care, RA Dalton successfully restored full functionality to the site’s wastewater infrastructure. Each system was left operating as designed, with all components tested and verified.

Benefits Delivered:

- Improved wastewater flow efficiency

- Reduced risk of pump failure and system downtime

- Extended lifespan of mechanical components

- Full compliance with environmental regulations

- Enhanced reliability of sewage and effluent systems

Regular servicing like this not only prevents costly breakdowns but also ensures compliance, environmental protection and peace of mind for our clients.

If your site requires professional wastewater system servicing, pump station maintenance, or sewage treatment plant support, contact RA Dalton today to schedule a consultation with our experienced team.