RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Future-Proofing Rural Properties: Farmhouse BioAir CW4 Installation

The Challenge

Two rural properties – a 4-bedroom farmhouse and an adjoining 3-bedroom cottage were relying on an outdated septic tank that no longer met environmental standards. With no suitable watercourse for effluent discharge, the system needed a complete overhaul to ensure compliance and long-term reliability.

Site Conditions and Initial Findings

Our site audit revealed several critical factors:

- Ground conditions: Mixed clay and sand, confirmed by borehole tests.

- Running sand encountered during test dig, requiring specialist shoring for excavation stability.

- Existing septic tank needing emptying and safe decommissioning.

- Space constraints: Installation had to fit within fenced-off land adjacent to the garden.

To ensure safety and compliance, it was essential that our QHSE team prepared detailed Risk Assessment and Method Statements (RAMS) for excavation, shoring and tank installation before commencing with any site works.

Designing the Solution

Following the site audit, RA Dalton developed a tailored solution to address the limitations of the existing traditional septic tank and ensure compliance with current regulations. The property’s wastewater system required a significant upgrade because there was no suitable watercourse available for treated effluent discharge, making a drainage field essential. The existing tank was outdated and posed a risk of environmental non-compliance, while the ground conditions demanded a design that could maintain stability and performance.

To overcome these challenges, we proposed installing a BioAir CW4 packaged sewage treatment plant.

The design also included a new drainage field, sized according to percolation test results, to ensure effective dispersal of treated water into the ground. By incorporating inspection chambers and planning for an isolated power supply, we aimed to create a system that was easy to maintain, energy-efficient and future-proof.

This approach was not only about replacing the old tank – it was about delivering a sustainable wastewater solution that protects the environment and guarantees compliance for years to come.

Clearwater BioAir CW4 Sewage Treatment System

The Clearwater BioAir CW4 was the ideal choice for this installation because it combines advanced aeration technology with proven reliability, ensuring exceptional wastewater treatment performance for rural properties. Designed for up to 12 people, the CW4 delivers high-quality effluent with a BOD5 reduction of 97.5%, meeting stringent Building Regulations and Environment Agency standards. Its robust yet lightweight construction allows for easier handling during installation, even in challenging ground conditions like mixed clay and running sand. The system is suitable for shallow dig applications, minimizing excavation depth and reducing disruption on constrained sites. With low-level visibility, it blends discreetly into landscaped areas, while its energy-efficient blower system and optional high-level alarm provide long-term operational security. Certified to EN 12566-3, the CW4 offers a future-proof solution that is easy to maintain, environmentally responsible, and backed by affordable service plans. These features made it the perfect fit for delivering a sustainable, compliant and reliable wastewater solution for the farmhouse and adjoining cottage.

Step-by-Step Installation

Our team delivered the project through a structured process:

- Site Setup – Temporary fencing, welfare facilities and delivery of materials, ensuring a safe working environment.

- Excavation & Shoring – Running sand required specialist shoring to stabilise the excavation for the new tank.

- Tank Installation – The BioAir CW4 unit was installed in a reinforced concrete surround, guaranteeing durability.

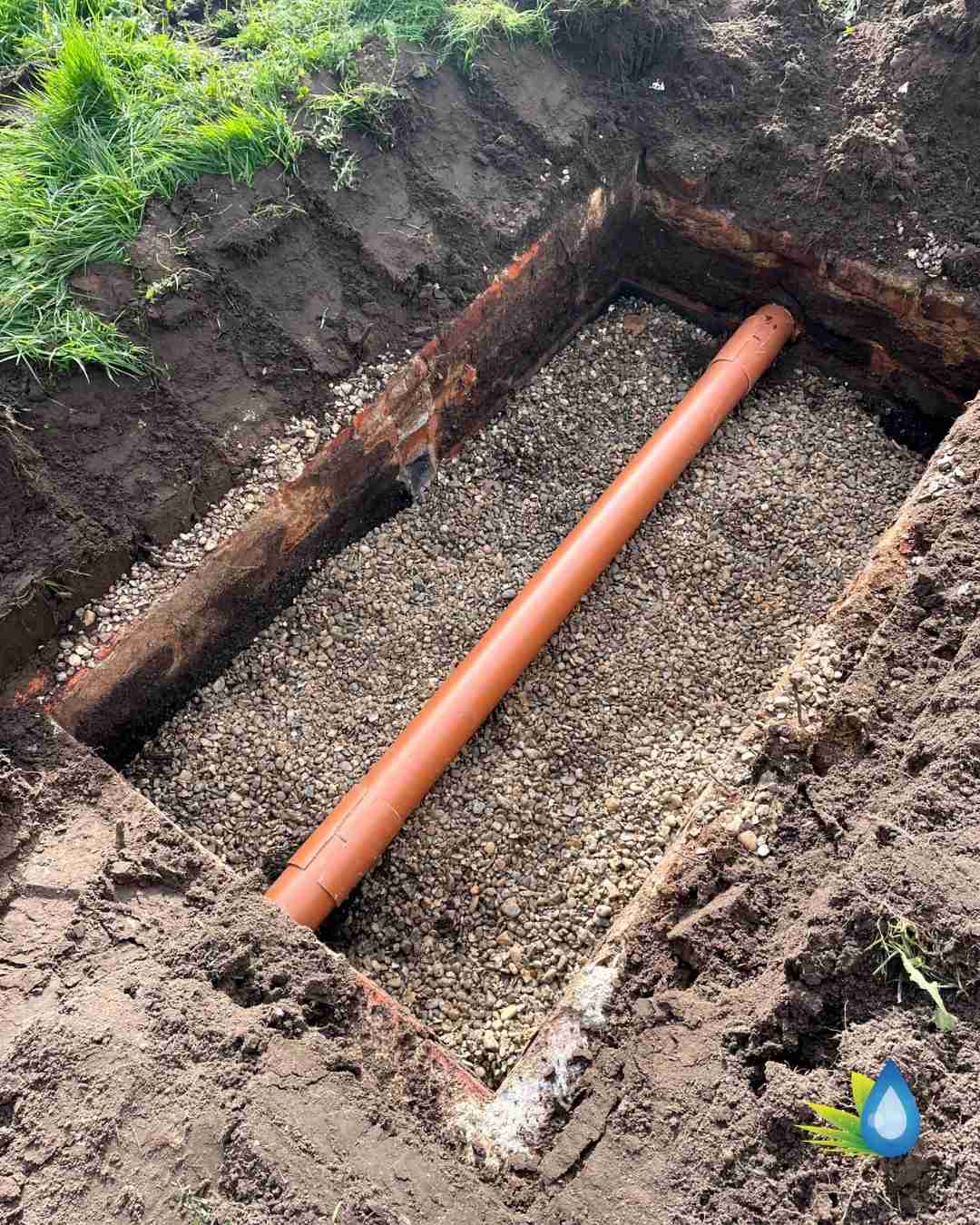

- Drainage Works – (Installation of four inlet inspection chambers (250mm–950mm deep) and one outlet chamber (circa 1100mm deep). Installation of roddable gullies for kitchen waste, surface water and foul water. 22m of foul drainage in concrete areas (reinstated by others). 29m of inlet/outlet pipework in gravel and grassed zones. 60m of drainage field using slotted 110mm pipe, bedded in clean washed gravel, protected with membrane and laid in 1500mm trenches. Jetting of surface water drain.

- Electrical Connection & Commissioning – SWA cable connected at the control panel, followed by full system setup and testing, plus installation of 20m of 50mm duct and 15m of 3-core 25mm cable.

- Decommissioning & Site Restoration – Old septic tank emptied, filled with gravel and covered with soil. Surplus excavated material removed via grab wagons.

The Result

The farmhouse and cottage now benefit from a modern, compliant wastewater system that is efficient, low-maintenance and environmentally responsible. The BioAir CW4 treatment plant ensures reliable performance for years to come.

Need a reliable wastewater solution for your property? Contact RA Dalton today for expert advice and installation.