RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

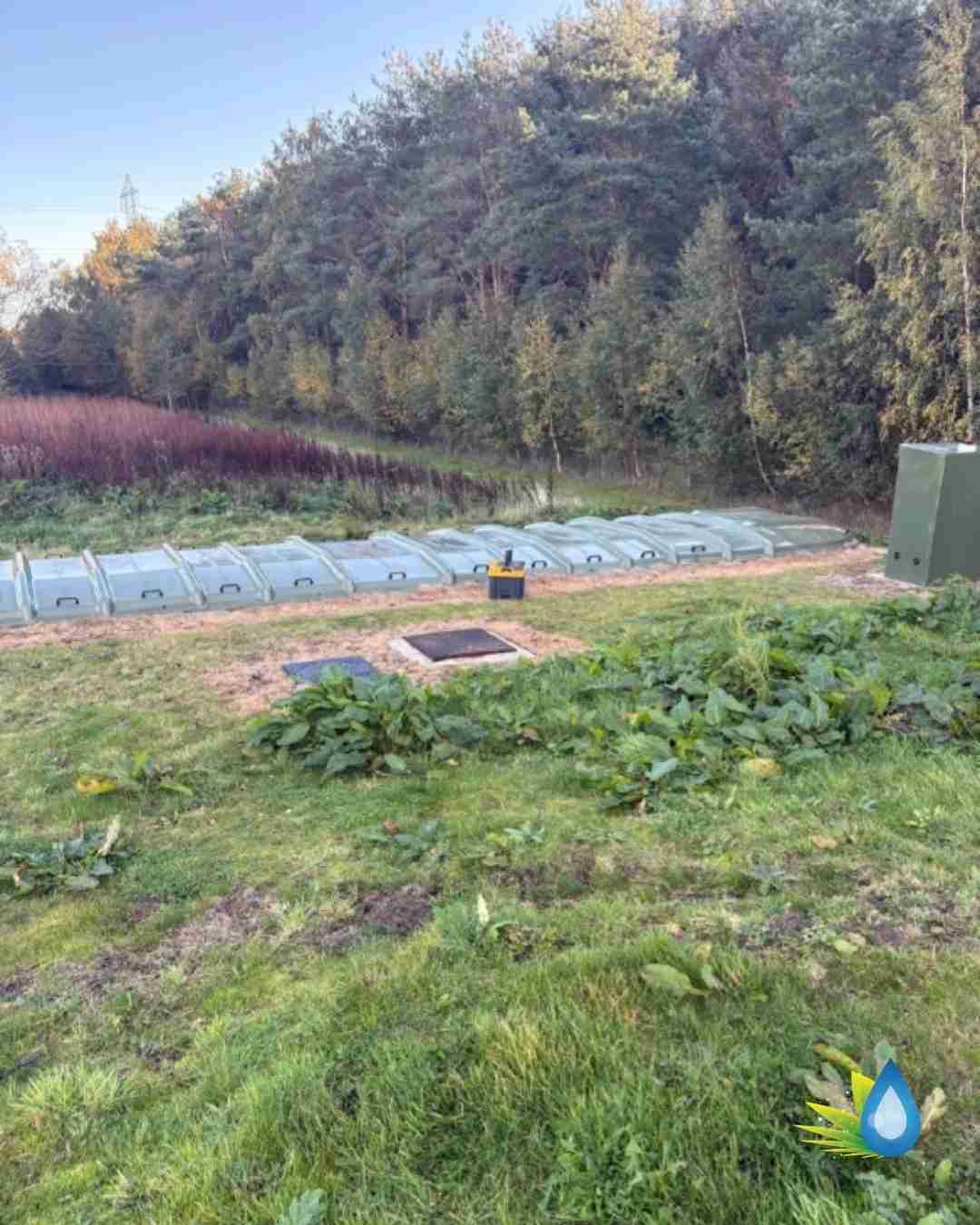

Maintaining Peak Performance: Expert Service of a Klargester NN BioDisc

Regular servicing and proactive maintenance are the key to ensuring your wastewater treatment system remains compliant and always runs efficiently. In this recent case study, our specialist engineers carried out a scheduled service of a Klargester NN BioDisc sewage treatment system, ensuring long term durability and optimal performance!

Initial System Assessment

Upon arrival, our engineer conducted a thorough inspection of all tanks. The primary tank showed a healthy crust formation, while the balance tank was relatively clean with minor sludge accumulation. The BioDisc primary chamber and discs were also in good condition, though some sludge buildup was noted. The final settlement tank had noticeable sludge, likely due to surface water hydraulics.

Mechanical and Electrical Checks

To guarantee optimal performance, we inspected all critical components:

- Airlifts and valves in the balance tank – all functioning correctly.

- Blower unit and connections – operating efficiently; filter cleaned to maintain airflow.

- BioDisc bearings and grease cartridges – in excellent condition.

- U-bolts, buckets and centre couplings – secure and intact.

- Motor gearboxes and electrical junction boxes – tested and confirmed operational.

- Sludge pump – checked for blockages and tested for proper function.

- Control panel and warning devices – verified to respond correctly to fault conditions.

These checks ensure the system remains mechanically sound and electrically safe, reducing the risk of unexpected breakdowns.

Recommendations for Continued Efficiency

To maintain peak performance and prevent excessive sludge buildup, we recommend:

- Emptying the primary tank and balance tank every 4 months.

- Fully emptying the BioDisc chamber on the same 4-month rota.

Why Routine Desludging Matters

One of the most critical aspects of wastewater system maintenance is routine desludging. Over time, solids settle in the primary tank, balance tank and BioDisc chambers, forming sludge layers. If these layers are not removed regularly, they can cause hydraulic overload, meaning the system struggles to handle incoming flows.

This can lead to:

- Reduced biological treatment efficiency – Excess sludge limits space for biological processes, reducing the system’s ability to break down waste.

- Carryover of solids – Sludge can pass into later stages, contaminating treated effluent and risking environmental compliance.

- Mechanical strain – Pumps, airlifts and discs work harder, increasing wear and the likelihood of breakdowns.

By scheduling desludging every 4 months, you maintain the correct retention time for biological treatment and prevent costly repairs or environmental issues. This proactive approach ensures the system operates at peak performance and extends its lifespan.

Need Expert Wastewater System Support?

At RA Dalton, we provide professional servicing for a wide range of sewage treatment systems, including Klargester BioDisc units. Whether you manage a domestic installation or a commercial site, our team is here to keep your system running smoothly.

Call us on 01388 537050 or email info@radalton.co.uk to book your next service.