RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Professional Maintenance of a Klargester BJ BioDisc: Precision Greasing & Full System Care

At RA Dalton Ltd, we pride ourselves on delivering industry‑leading expertise in the servicing, maintenance and emptying of wastewater treatment systems. This recent project showcases our team’s meticulous approach to the service and empty of a Klargester BJ BioDisc, ensuring long‑term reliability and optimal system performance.

Our engineers arrived on site and immediately began a structured inspection, removing the lids and confirming that the BioDisc system was operating correctly. A full empty and service was completed to the highest standard by our team.

Comprehensive BioDisc Maintenance

To ensure the Klargester BJ BioDisc continued to operate at peak performance, our engineers carried out a full and methodical service. After opening the system and confirming initial functionality, they proceeded to strip down every bearing, meticulously cleaning and packing each one with fresh grease to restore smooth operation. All grease cartridges were replaced, as the existing units had fully depleted, ensuring the BioDisc would receive consistent lubrication going forward. The team then inspected every U‑bolt, tightening them to the correct specification to maintain structural stability. They also examined the BioDisc buckets, confirming that each one was functioning as designed and contributing to effective treatment performance.

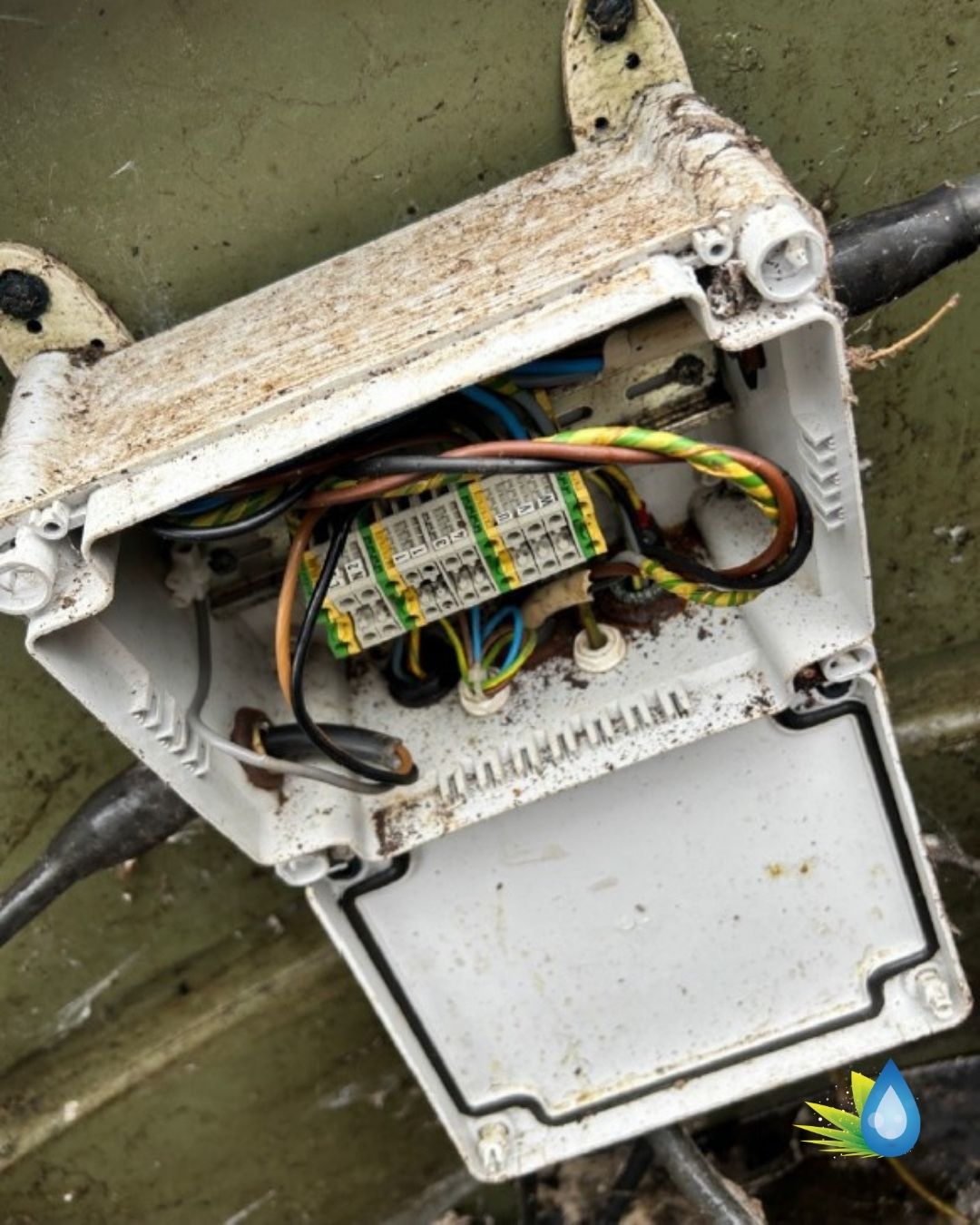

The engineers tested the loss‑of‑rotation safety system, verifying that it communicated correctly with both the control panel and the external beacon – a crucial safeguard for early fault detection. They inspected all internal junction boxes, ensuring they were dry and that every electrical connection was secure. The motor was then assessed under load to confirm it was running smoothly and rotating the disc at the correct speed. Finally, the full control panel underwent a functional check to ensure all indicators, alarms and operational settings were performing as intended. New warning signage was added to the kiosk, along with a fresh sample point sign at the outlet manhole, before the system was left fully operational and performing reliably.

The Importance of Grease

A critical part of any BioDisc service is ensuring that all bearings are correctly greased and that automatic grease cartridges are functioning. These components play a vital role in the longevity and reliability of the system:

- Properly greased bearings reduce friction, preventing overheating and premature wear

- Fresh grease cartridges ensure consistent lubrication over time, especially in systems that operate continuously

- Neglected lubrication can lead to bearing failure, motor strain and costly breakdowns

- Routine maintenance significantly extends the lifespan of the BioDisc and reduces long‑term repair costs

By replacing empty cartridges and re‑packing bearings, our engineers safeguard the mechanical integrity of the system and ensure smooth, uninterrupted rotation of the BioDisc.

Delivering Reliability, Compliance & Peace of Mind

This project demonstrates RA Dalton Ltd’s commitment to delivering high‑quality wastewater servicing, Klargester BioDisc maintenance and specialist mechanical expertise. With every service, we ensure systems remain compliant, efficient and ready for long‑term operation.

Your Trusted Partner for Wastewater Service & Maintenance

If you want the same level of precision, reliability and specialist care for your own wastewater treatment system, the team at RA Dalton Ltd is ready to help. Our team are industry experts in servicing, wastewater system maintenance and treatment plant remedials, delivering dependable results that keep your system compliant and performing at its best. Whether you require a routine service, an emergency call‑out, or a full system assessment, we provide nationwide coverage and unmatched technical expertise.

Get in touch with RA Dalton Ltd today to schedule your next service and experience the difference that true wastewater specialists can make.