RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

Routine Service Ensures Optimal Performance of Sewage Treatment System

At RA Dalton, we pride ourselves on delivering reliable and professional wastewater treatment services across the UK. In this recent visit, our engineers were tasked with a scheduled service of a Conder SAF250N10 sewage treatment system – an essential component in maintaining high standards of environmental compliance and system efficiency.

Initial Inspection and System Assessment

Upon arrival, our team found the system operating correctly with no immediate faults or alarms present. Our engineer began by opening the kiosk doors to inspect the internal components, starting with the blower units. These were pressure tested and confirmed to be producing the correct levels required to aerate the system effectively, ensuring the biological treatment process remains within optimal parameters.

Electrical Panel and Alarm Testing

Next, we examined the control panel housed within the kiosk. All connections were secure, with no signs of wear or looseness. We then carried out a full test of the alarm facilities, verifying that faults were correctly displayed on the panel and that the beacon activated as expected during simulated fault conditions. This ensures that any future issues will be promptly flagged for attention.

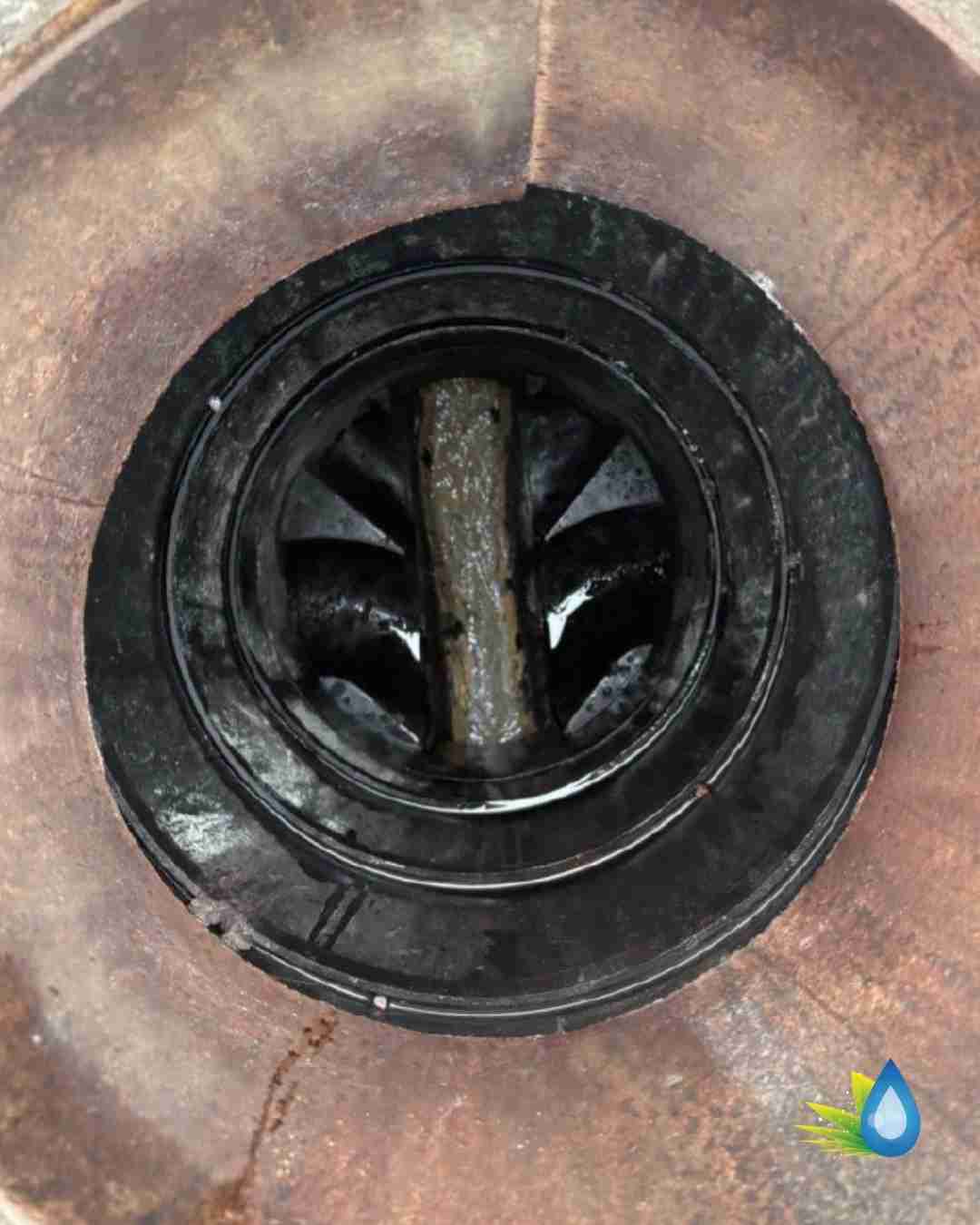

Sludge Return Pump Maintenance

We then turned our attention to the sludge return pumps. Both units were lifted from the tank and inspected – no blockages or damage were found. Each pump was tested multiple times using their control floats, confirming correct rotational direction and smooth operation. Once reinstalled, further testing confirmed they were functioning as intended.

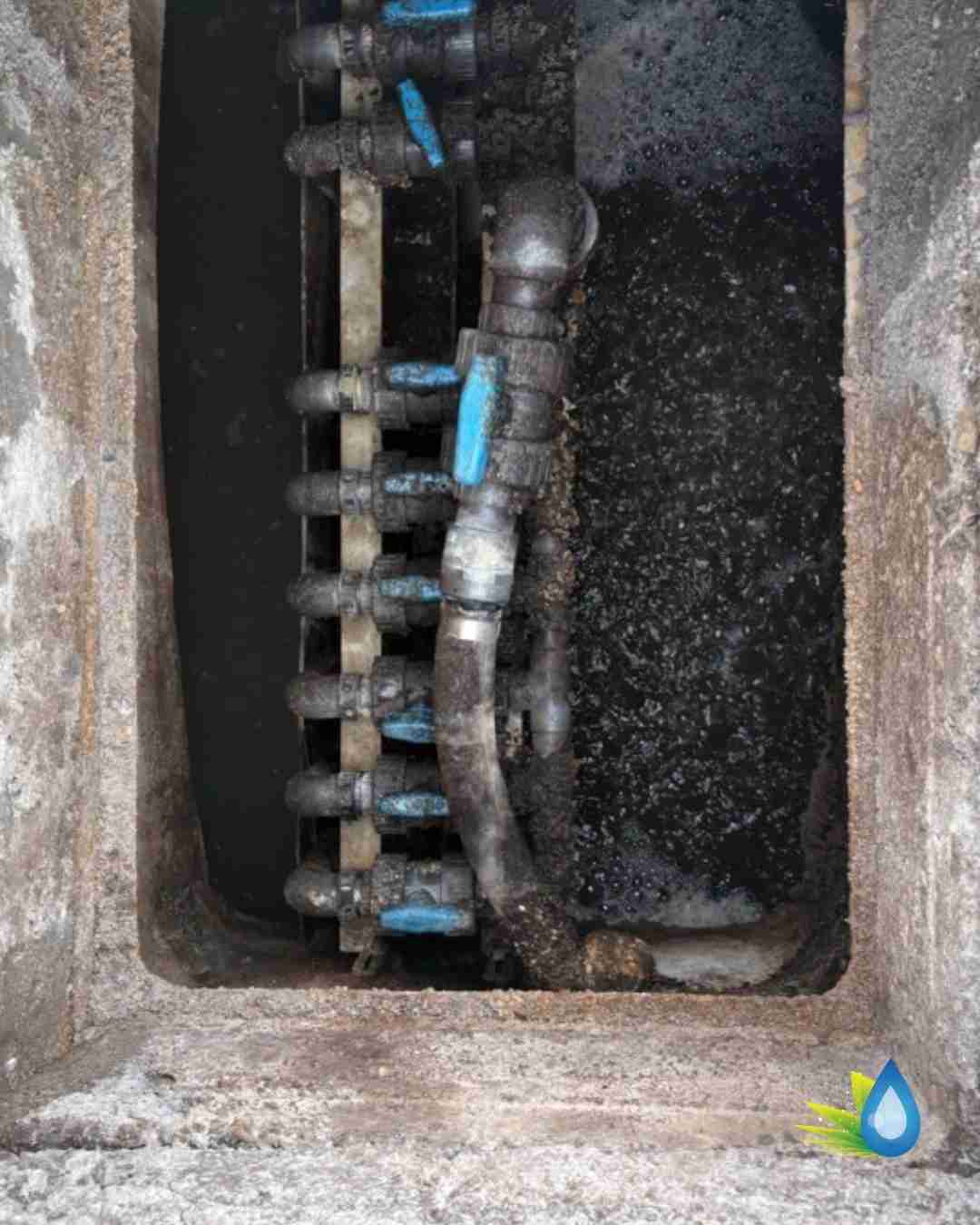

Pressure Alarm and Pipework Checks

To complete the electrical checks, we tested the loss-of-pressure alarm and beacon, both of which responded accurately and reliably. We also carried out a thorough inspection of all pipework within the tank. Everything was in good condition, with no signs of leaks or deterioration. All air lines and valves were operating smoothly and no air leaks were detected.

Air Intake Filter Servicing

Finally, we serviced the air intake filters. The right-hand filter was lightly soiled and received a brush-down to remove accumulated dust and debris. The left-hand filter was replaced entirely to ensure continued clean airflow into the system.

Final System Status and Quality Confirmation

With all components inspected, tested, and confirmed to be in good working order, the system was left operating exactly as it should. This routine service reinforces the importance of regular maintenance in preserving system integrity, preventing faults, and ensuring consistent wastewater treatment performance.

At RA Dalton, we’re committed to keeping your systems running smoothly because clean water and peace of mind go hand in hand.

If you require expert advice on wastewater treatment management, please contact RA Dalton on 01388 537050 or email us at info@radalton.co.uk