RA Dalton Success Stories

RA Dalton Ltd are the Klargester number one accredited installer covering the whole of the UK.

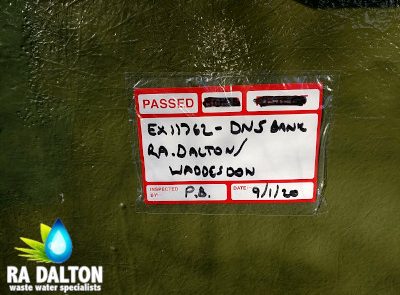

Waddesdon Manor – The installation of a Kee DN5 and Klargester Balancing Tanks.

In the Vale of Aylesbury we recently had the pleasure of carrying out an installation of a new sewage system to serve Waddesdon Manor, a National Trust property that receives over 460,000 visitors a year. The renaissance-style château has featured in a number of TV Programmes and films and is open to the public for the majority of the year.

Waddesdon Manor was built in the late 1800s for Baron Ferdinand Rothschild, and is now cared for by the Rothschild Foundation, in conjunction with the National Trust. On site, in addition to the manor, visitors can discover an Aviary, Wine Cellars, extensive gardens and cafés/ restaurants.

In January each year, Waddesdon Manor temporary closes its doors for a deep clean and the undertaking of conservation practices. This proved to be a prime opportunity for us to step in and look at the waste management system on site.

The Sewage treatment proposal.

As Waddesdon Manor is an extensive site, it was vital that the set up could deal with the capacity and the different facilities. Before any works began on site, the wheels in the background were firmly in motion, in the form of extensive discussion between Alistair Dalton, the site, and an experienced consultant from Watercourse systems ltd. These took frequently place to ensure the requirements were adequately met and the course of action was agreeable.

The proposed units were the Kee Process DN5 Managed flow disc complete with ST5 Final settlement chamber, a Klargester 59m3 Primary settlement chamber and a Klargester 79m3 balance tank. These were the ideal set up for the site to deal with the predicted increased flow and visitor count.

Working alongside Kee Process we were able to determine the system size that was necessary to handle the daily flow and BOD loadings, inclusive of extra capacity for those busy summer days. For improved effluent quality a sludge return chamber and re-circulation pump was installed so the wastewater went through the process more than once.

Within the Balance tank an airlift was also installed to stop all of the effluent settling in the system and ensuring that the treatment process was continuous.

The Monumental installation.

Understandably, with the sheer size and quantity of tanks we were installing, there was a requirement for an insurmountable volume of concrete; over the month we were on site there was in excess of 260m of concrete supplied to site.

Along with the concrete supply a large variety of machinery was also required which included, but was not limited to, a 21 ton Excavator for digging the required depth for the balancing tanks and Kee units, a 9 ton dumper for tracking the spoil to an agreed location on site. A 5 ton excavator was utilised for the some of the tighter requirements and smaller installs, a 6 ton Dumper for leading the concrete in to the installation location, and last but not least a 3 ton Excavator for all tidying up works on site.

On top of the machinery we had on site for the groundworks, we also required a crane to offload the colossal Kee Unit as, working within site restraints, this was the most practical and precautionary way to get the new treatment plant into the excavation area.

Getting the job done right.

At all our locations conforming to site constraints and health and safety protocols are of upmost importance. Whilst work was being carried out our site was surrounded by safety fencing and signage at all times, and site times and parameters that were laid out by the customer were adhered to.

Over the duration of the job we had 3 to 4 installation engineers on site each week, working quickly and efficiently as a team to keep within the deadline whilst never once compromising the integrity of our work. Setting off in the early hours of Monday morning, arriving on site mid-morning after 6 hours of travelling, and often not returning home until late Friday evening, their efforts were not only appreciated but also evidenced in the photographic log taken whilst on site.

Here at R A Dalton we pride ourselves in our work no matter the scale of the job, everything from a Klargester Bioficient 1 to the installation we have outlined here.